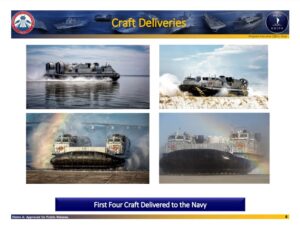

The Navy is planning to have four Ship to Shore Connectors (SSCs) delivered per year and is progressing through testing before initial capability planned for 2023. “We’re positioned very well where we’re going to be at four deliveries per year going forward. We think that’s achievable. We’ve had two deliveries each of the last two years. We’ve got a nice full production line now, so the pump is fully primed and now there’s not anything backing it up at the…

By

By