Future Frigate (FFG(X))

-

Navy/USMC

Navy/USMCNavy Official Says Frigate Design Expected This Summer, Confirms Service Still Needs Sixth-Gen Fighter

A top Navy official Thursday provided lawmakers with updated figures on Constellation-class frigate design progress following significant delays and confirmed the service is still looking into ultimately procuring a new […]

Tagged in: -

Navy/USMC

Navy/USMCWittman: Navy Must Decide If Frigate Should Be Fixed Or Scrapped

NATIONAL HARBOR, Md. – Lawmakers on Wednesday questioned the Navy’s decisions on how it builds and maintains ships, with a top member of the House Armed Services Committee (HASC) questioning […]

Tagged in: -

Navy/USMC

Navy/USMCFormer Navy Acquisitions Chief Says Frigate Parent Design Mod Plan Flawed, ‘A Lot Harder Than It Sounds’

The former Navy acquisition chief this week admitted the Navy’s plan to modify a parent design for the Constellation-class frigate was more difficult than the service thought, leading to major […]

Tagged in: -

International

InternationalNorway And France Start Closer Defense Coop As Norway Plans To Compete New Frigate

The Norwegian and French ministers of defense agreed to work toward closer defense cooperation on things like maritime surveillance earlier this month as Norway ramps up its plans to acquire […]

Tagged in: -

Navy/USMC

Navy/USMCFrigate Manager Says Design To Finish This Year, Delays Because Parent Design Mods Not Understood

The program manager for the Constellation-class frigate this week said the Navy plans to finally complete design of the ship this year and commented some of the delays were due […]

Tagged in: -

Navy/USMC

Navy/USMCTrump Criticizes Frigate Cost Increases

In a recent interview, President-Elect Trump criticized problems in the Navy’s Constellation-class frigate program, attributing design change issues to the Biden administration. According to a transcript of the interview with […]

Tagged in: -

Navy/USMC

Navy/USMCFrigate To Need Distributed Shipbuilding Like Subs, Early In Second Yard Search Says Navy Official

The Navy official who manages the program office with the Constellation-class frigate said the Navy is looking to distribute production like in recent submarine construction moves to work around workforce […]

Tagged in: -

Navy/USMC

Navy/USMCNavy Investigates More Frigate Design And Construction Sources Amid Major Delays

The Navy recently issued a Request For Information (RFI) seeking more sources able to support Constellation-class frigate design and follow-on construction amid significant delays in the program’s schedule. The notice, […]

Tagged in: -

Navy/USMC

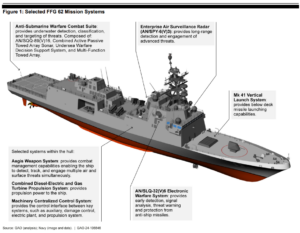

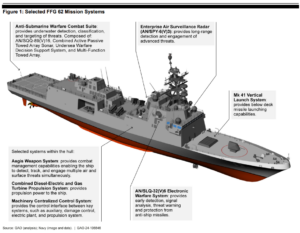

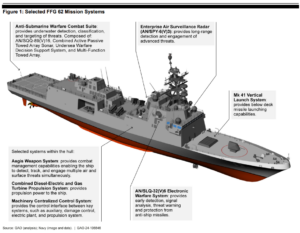

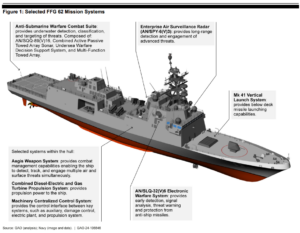

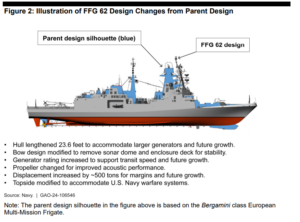

Navy/USMCGAO Finds High Risk In Some Frigate Systems

A recent Government Accountability Office (GAO) report found that while the Navy’s new frigate class is using many systems proven on other ships, the propulsion and machinery control systems have […]

Tagged in: -

Navy/USMC

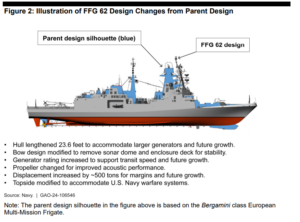

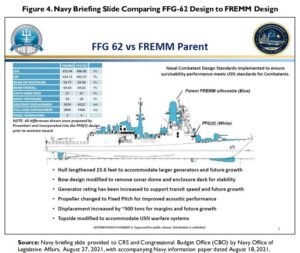

Navy/USMCGAO Argues New Frigate Delayed Because Of Navy Design Changes, ‘Botched Metrics’ Obscured Progress

A new Government Accountability Office (GAO) report laid out in stark terms how the Navy started with a new frigate program meant to reduce delays and costs but significant design […]

Tagged in: